Two terms you likely hear over and over again as a project manager, supervisor or team leader are "quality control" and "continuous improvement." You can apply these broad concepts without fail to any industry, project, or situation.

When you apply and use them correctly, they will become second nature, simplifying and improving the way you work. However, if you don't understand their significance, or you stay at their broad definitions and don't dig deeper to find concrete, measurable ways of applying quality control and continuous improvement to your business, you won't benefit fully.

Learning the difference between quality control and continuous improvement is essential, even if you already use these terms and concepts. These terms have become so common over the past decade that, in some cases, they have lost their impact and are seen as slogans, not useful day-to-day tools. Once you understand the major and nuanced differences between quality control and continuous improvement, you will see them as two very powerful approaches to running a leaner and more efficient business with measurably higher quality.

What Is Quality Control?

Competition is fierce, not only from traditional competitors but also from new, innovative products and services that are rewriting the rules of how business is done.

If you can't supply quality to your customers in terms of product, service, delay, reliability, etc., they are going to find it elsewhere. The very first step is to stop looking at quality as a weight to carry and, instead, see it as one of your major strong points.

This adversarial view of quality stems from the push decades ago to add quality after the fact. When the big wave of quality tools - such as Lean Manufacturing, Kaizen, 5S and Kanban - and concepts rose to prominence in the 1980s and 1990s, they were often grafted onto existing processes, tools, and methods, making them cumbersome and burdensome.

Quality was viewed as an extra operation, step, or layer, and it added to everyone's workload. If you are an experienced manager who saw the addition of a quality function or department in your business decades ago, you will recall how disruptive it often was. Those of you who are just starting your careers likely didn't experience this change and always knew quality as an integral part of how you work.

That concept of integration is key. You need to view quality as an integral part of everything you do. The Southeast Asian country of Indonesia has many unique languages, but many of them do not have a word for religion. This is because, for many Indonesians, religion is non-dissociable from everyday life. The concept of life without religion doesn't exist, so there was never the need to create a word for it.

This is how you should view quality in your organization, department, or service. Of course, the word quality exists, but you can't see it as something that is in addition to or grafted onto your products, processes, or services.

If you are responsible for an area of your business that is lacking in terms of quality, you will see much greater results if you work to integrate any new concepts and methods into the workflow - not treat quality as a unique step to be performed in a bubble.

The Beginnings of Quality

The actual concept or understanding of quality management goes back a very long time, but it was sometime after the Second World War when the idea of quality, as we know it today, started to spread across the United States. The generally recognized definition of quality includes the notion of being free from defects, deviations, or significant variations and responding to an initial intent or planned result.

When quality was first being studied, the focus was primarily on detecting anomalies and removing them from circulation. This involved a thorough inspection or measurement of the process or product in question. Early quality inspection was deemed successful if it captured 100 percent of the non-conforming parts.

The problem with this tunnel-vision view of quality is since it lacks integration, the detection of an anomaly does not directly communicate upstream to the source of the anomaly and modify or correct it. One example that dates from WW2 highlights the problem well:

- Guns and bullets were typically manufactured in the same factories and states and would work when used together.

- Bullets that were manufactured in one factory or state would not always work in guns from another factory or state. At best, the gun jammed, and the bullet would be removed and replaced with another. At worst, a soldier found himself unarmed face-to-face with the enemy.

- If a soldier pulled one bullet from a box, and it was defective, he had no way of knowing if the next one was - or the one after that, or the whole box. Was he unlucky and pulled the only bad one out of a box of 20? Or was every bullet bad? Every second one? There was no time for this kind of question out on the battlefield, and the results often had serious consequences.

- Gun and bullet manufacturers applied a basic quality inspection on 100 percent of their production. This would mean checking the diameter of each and every bullet produced, which obviously added significant time and manpower - and therefore cost "” to their manufacturing.

This was quality as a Band-Aid solution. It did help solve one issue, but in no way addressed the cause of the problem.

Once the manufacturers started measuring the bullets and discarding the defective ones, they had addressed half of the issue, and the soldiers in the field were much more confident their guns would fire. At this stage, we were understanding the concept of quality but hadn't yet instituted quality control.

Making the Leap From Quality to Quality Control

The control step of quality control came when the loop was closed. A defective bullet that was tossed in the garbage had no bearing on how many other defective bullets were produced. Without looking into why defective bullets were being produced, nothing stopped the manufacturer from creating more. Remember, if you can make a mistake one time, you can potentially make it every time. Even without being an expert in bullets, we can imagine several different potential causes of defective bullets:

- Raw material - Wrong brass tube diameter, wall thickness, or surface finish;

- Manufacturing - Incorrect machining, cutting, assembly, or joining;

- Handling - Dropping, bending, or clamping improperly;

- Conception - Poor design leads to a possible error in assembly;

Analyzing these causes allows us to go back to before the errors were made and either remove or correct them. That is the control portion of the quality control. With measurements, tracking, and process control, nowadays, we can automate this loop and have real-time corrections to our processes to eliminate errors as soon as we detect them.

With modern quality control, we can even go a step further and anticipate the drifting of a process, making corrections to avoid defects and errors before they happen. Statistical analysis and computer-aided simulations give us the information we need to maintain strict control over our systems and processes. Keep in mind that quality control is just a single component of a bigger system called quality management.

Understanding Continuous Improvement

While continuous improvement is related to quality control, it is important to realize continuous improvement has its own scope and application. While the idea of continually improving may seem bluntly obvious, without a definition and concrete application of the principle in your workplace, you will find that it doesn't occur as naturally as one might assume.

Look at a simple example in life: jogging. When you first take up a sport for general fitness such as jogging, you usually time yourself and measure your distance. You push yourself each time to jog faster or jog further. Even a small amount of improvement encourages you to do better the next time. When you fall behind your previous or average performance, you work to get back to where you were.

If you jog for a long time, you'll eventually get into a groove. You'll know what you're capable of and how far you jog in a certain amount of time. You're content to maintain your level, and it just feels right.

This is what happens on a professional level if you don't use tools and methods to encourage, facilitate and monitor your workplace continuous improvement. You might initially find improvements to make, the low-hanging fruit that is obvious and easy. You'll be satisfied when you see relatively significant improvement with minimal effort. Very quickly, however, you risk finding your new normal, comfortable and satisfying level that doesn't lend itself to further obvious improvements. At this point, you're in cruise control mode, and you're not likely to exit it until a problem or crisis arises.

However, if you put the effort beforehand into establishing a solid, measurable, and proactive continuous improvement process, you have the motive force pushing every improvement and constantly drive positive gains. Many excellent tools have been created to formalize and pilot continuous improvement in a business and industry environment, and one of the most common and useful is the Deming Cycle.

The Continuous Improvement Cycle

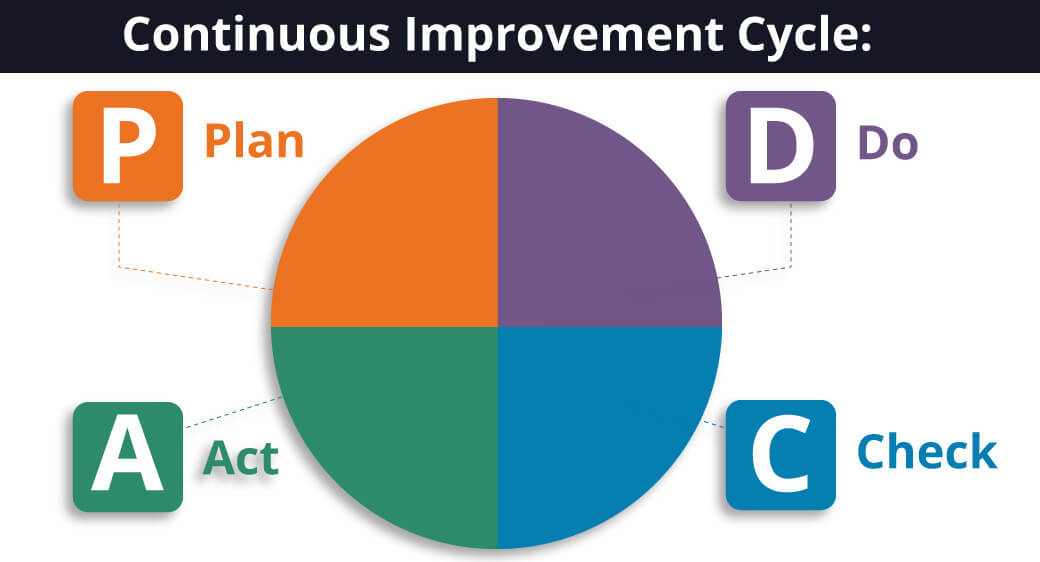

Named after its inventor, Walter Deming, the cycle is a visual representation of the steps to take for continuous improvement. Also called the PDCA cycle is represented by a wheel, divided into 4 quadrants, and placed on an inclined slope. The quadrants each represent a different action:

- P - Plan - Plan the improvement you want to make, based on a study, observation, and calculation.

- D - Do - Do the actions, make the changes, make the modifications and update the procedure.

- C - Check - Check the results and implications of the improvement, using measurements and statistics when possible.

- A - Act - Act on your observations and make any modifications or further improvements necessary.

As you perform each step of the PDCA cycle, you can picture it being rolled up the incline. The notion of the incline is significant: It acknowledges that continuous improvement isn't easy or without resistance. At times, the incline may reduce, and you may find improvements easier to discover and implement. At other times, the incline will increase, and you will struggle to advance. At these moments, the structure and methodology of your continuous improvement system keep you on track and maintain focus on your objectives.

How to Link Quality Control and Continuous Improvement?

It might seem as if quality control and continuous improvement were two independent concepts with minimal overlap. However, it is better to marry the two as much as possible and consider how you can combine them to provide maximum control over your services, programs, or processes. The most popular and effective tools - such as Lean Manufacturing, Total Quality Management, and 6-Sigma - are all designed to promote exceptional quality control while embracing the spirit of continuous management.

The same goes for our Kanban software. We designed it to be easy to use and flexible enough to apply to any type of business or industry, such as IT, software, marketing, operations, or manufacturing. The visual layout and customizable interface mean you can tailor your boards to suit your specific needs. With our help, you can create your workflow in a way that makes sense and is easily tracked. With the inputs from your processes, your Kanban applies the concepts of lean manufacturing to find ways to optimize and improve your workflow.

This is the continuous improvement aspect.

You'll track important metrics in real-time and can easily adjust schedules, budgets, and communications. Since every user will have specific needs and requirements, we built in many customizable features and options.

It is also easy to see how you can use our powerful online project management software as a quality control tool. Having real-time access to all of your project timelines, details, specifications, and analytics means you can track and adjust quality-related issues before they have the chance to grow.

A Significant Change

We started out by saying that focusing on quality and continuous improvement shouldn't be seen as an added workload or additional steps to how you work today. However, if today your organization hasn't integrated these concepts, there WILL be a moment of adjustment as you institute them. When planned properly and designed for complete integration, you will quickly see that your quality control and continuous improvement tasks actually simplify how you work, streamline your processes and create new efficiencies.

For established businesses, team members can have reservations about making a change. It's human to resist change, which is why you need to anticipate the potential resistance you might encounter as you work towards a new way of doing business. To streamline change:

- Always explain why you're making changes - Help your teams and employees see the big picture and highlight the expected improvements in productivity and efficiency. Use concrete examples when possible. While explaining a reduction in wait times, physical stock, or marketing costs in terms of a percent may be useful to management, your employees might better understand and appreciate examples in terms of days, square feet, and dollars.

- Clarify the goals of the changes - Explain the quality control tools and methodology you are implementing to improve quality, not simply track it. You want to make 100-percent good bullets. You don't want to simply catch the bad ones and throw them out.

- Focus on training - Give your employees the opportunity to practice with the interface. Let users experience firsthand how intuitive and productive quality control and continuous improvement can be.

Don't assume just because you have grasped the utility of these two major business concepts that everyone will right away.

Also, think in terms of scalability. Thinking three, five, and 10 years out, you want your continuous improvement and quality control systems to help grow your business and be adaptable to any changes you make. If the markets change - either for better or worse - you don't want to have to toss your systems out the window and start from scratch. If you add projects or missions from other global regions, you want to be able to integrate them seamlessly into your successful way of doing business with as little disruption as possible.

Start Today

Does implementing new quality control and continuous improvement strategies sound like a lot of work? It shouldn't.

It's important not to lose sight of your ultimate goals:

- Quality Control: Quality needs to be active, not passive. Don't just observe your quality, control it. Refine your checks and metrics, so you detect slight deviations from normal or, better yet, predict changes and discrepancies before they happen. That way, you can avoid them completely.

- Continuous Improvement: Your business never takes a break, and neither can your improvements. Build continuous improvement into everything you do so it is impossible to dissociate from how you work. Use tools such as the PDCA cycle to drive your continuous improvement.

You will quickly see how you can improve your efficiency and productivity. You'll discover how easy it is to integrate the concepts of continuous improvement and quality control organically.

Alex Novkov

Content Lead

Energetic and practical, passionate about social media, creative writing, heavy weights, and outdoor activities.