The term continuous improvement is fairly self-explanatory. It almost seems too simple, but this industry buzzword is about continually improving your business, processes, and way of working.

How you go about studying, planning, implementing, and evolving that improvement is where it gets more complicated. You need to encourage a philosophy of constant, logical, and sustainable improvement throughout your organization. This allows continuous improvement to go beyond being a slogan on a poster, so it becomes the way your company operates at all times.

While continuous improvement can range from simple changes in the day-to-day workings of your company to major shifts in focus and procedures across a global structure, in all cases, you will require the right instruments to achieve success and keep it going.

Why Is Continuous Improvement Important?

"Life begins at the end of your comfort zone" - Neale Donald Walsch

There's a reason humans often resist change: There's a comfort in what we know. While the call of the unknown is appealing to some, it is a natural and reassuring thing to resist putting ourselves in new situations.

In the business world, this is no longer possible. In times gone by, it was often possible for companies to "rest on their laurels" and maintain the status quo with their products and services because people trusted their brands and products and knew what they were getting. There are several reasons why this doesn't work anymore:

- There's More Competition Than Ever: Competition is a good thing. It gives us a basis for comparison amongst our peers and pushes us to do better. But it also means we aren't the only ones offering a certain product, service, or feature. When there's limited competition, you can more easily defend your corner of the market, but in today's competitive climate, you don't get a moment's rest.

- It's a Global Marketplace: For most industries and businesses these days, you not only have to be concerned about local competition but also with foreign competition. More and more borders are coming down, and mature products and services from other markets can catch you by surprise. If you don't watch what's going on elsewhere in the world and prepare for it, you won't be prepared to deal with it when it does arrive.

- Information is Everywhere: Consumers are connected 24/7 these days. They have access to information at their fingertips. For example, 85% of consumers use the Internet to locate businesses that meet their needs. Whereas previously, a product, service or marketing plan was designed for longevity, nowadays, you need to be ready to react to shifts and trends in the market. It's important to use the speed of information flow to your advantage and not sit and watch it fly by.

- Dynamics are Changing: The old walls around products and services have been torn down, and intelligent, flexible companies are reaping the rewards. Mobile apps are turning the taxi industry upside down. Online banks are offering an alternative to brick-and-mortar banks. Home delivery is changing the way we buy everyday products. That doesn't mean "traditional" businesses are finished - it just means they need to evolve.

"Same old, same old" won't work anymore. But that doesn't have to be seen as a bad thing. On the contrary, realizing and accepting that there is a new way of doing business is exciting and can create many great opportunities for you and your organization, company or group.

Not a New Concept

To be clear, the continuous improvement concept isn't a new one. Formalized in the 1980s in countless textbooks and publications, the notion that we should always strive to do our jobs better has existed for a very long time. It comes naturally to some people. Look at the case of the caveman:

- The poor caveman struggled to catch his food, which was too fast to catch by hand.

- He discovered that if he used a stick, he had a longer reach and a better chance.

- Throwing the stick gave an even better range and improved his odds of catching his prey.

- Adding a sharp stone to the end of the stick meant even greater success.

- Involving other cavemen in the hunt also multiplied his chances of catching dinner.

This is continuous improvement. It's not finding a method that works and sticking with it. It's looking at where you are today, setting a goal, and doing what needs to be done to reach that goal. Once that goal is met, you start again, finding ways to improve further. It doesn't matter what kind of industry or business you're in - a continuous improvement approach is necessary to keep ahead of the game.

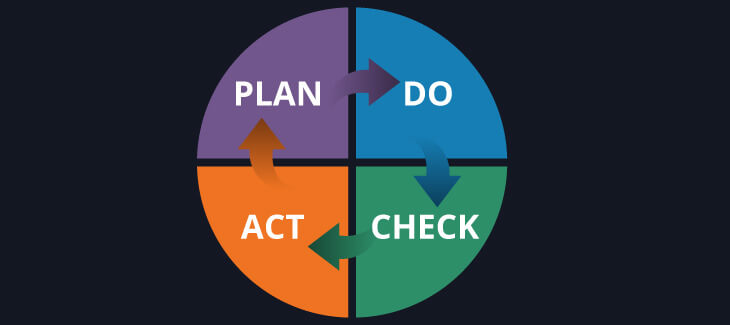

With the wealth of information available on the subject of continuous improvement, it can be difficult to know where to start. What we suggest is always starting with analyzing your current situation. You need a full understanding of how you operate today so you can follow the principles of PDCA. First, you establish your baseline, your starting point. Then you:

- PLAN: Plan your improvements, including setting goals.

- DO: Put in place the actions required for improvement.

- CHECK: Measure your success relative to your baseline.

- ACT: Adjust or tweak your changes.

This process is often represented in the graphical form of a wheel, known as a "PDCA wheel" or "Deming wheel" after the creator, Dr. W. Edwards Deming. As you progress through each step, you keep the wheel moving, representing continuous improvement. When you arrive again at your baseline stage, you take into account your previous improvements and plan the next improvements.

The Continuous Improvement Project - Make It a Strategy

Even if your company or organization doesn't actively promote a continuous improvement process today, that doesn't mean you don't do any continuous business improvement. It just means that you're probably not doing it as systematically or effectively as you could, and you might not be deploying changes from one sector or area to others that could benefit.

This is where the notion of a culture of continuous improvement comes into play. When you first broach the subject of continuous improvement with your employees and collaborators, most will agree on the necessity but not necessarily know where to begin. Creating a formalized plan that works for your structure is critical.

There are many reasons why formalizing your continuous improvement strategy is important:

- It gets everyone using the same language. This is key when you're looking to deploy lessons learned and best practices across your facility, processes and business units. Formalizing documents, procedures and work instructions makes it easier to get everyone on the same page.

- It creates a mindset. Instead of viewing continuous improvement as something to restart with every new project, a formalized and consistent approach to continuous improvement teaches people that the system is inherent to how your business runs. It isn't something you add to how you work - it becomes how you work.

- It makes people accountable. When continuous improvement permeates all levels of your organization, it stops being one person's job and becomes part of everyone's job. Knowing that your business never stops evolving helps your employees see where they can be an active part of continuous improvement.

- It reinforces the importance. In this day and age, it's easy to get lost in corporate-speak and boardroom slogans. Continuous process improvement needs to be treated as an integral foundation for your organization, and formalizing how you approach it makes it more concrete.

You'll find that once you have established rules and guidelines for your continuous improvement, it will be easier to include it in all aspects of your business. And don't forget you need to apply the concept of continuous improvement to your continuous improvement system! What works today might not be adequate in the future, so make sure you're constantly analyzing and evaluating your continuous process improvement methods and making improvements and corrections where necessary.

Change for Change's Sake

One danger, especially if you don't actively pursue continuous improvement with your teams and employees today, is that you might feel pressured to make changes simply to show that you're not sitting still. An effective continuous improvement strategy requires a long-term, sustainable mindset and may not bear fruit in the extreme short term.

Continuous improvement isn't change for the sake of change. It's adding value to the way you operate. If, after analysis, you see certain aspects of your processes and procedures are effective and efficient, don't feel like you have to force a change. Simply continue your analysis of other aspects. You will always find an area that can benefit from improvement.

For example, in the case of a review process for projects that you have in place, you might make the following observations:

- The steps in place may all be necessary. Don't remove or consolidate steps if they serve a purpose and add value to the process simply to show you've made an "improvement." Look closely at each step and each actor and understand the interactions before you make any changes. Resist the urge to assume that "fewer steps" is automatically an improvement. Instead, search for a fundamental understanding of the entire process and make improvements based on that.

- You may need to include other departments and divisions to understand the impact of improvements you have in mind. Be careful not to wear blinders when you're looking to improve your review process. Be aware that the inputs and outputs of your process relate to many other actors, such as suppliers, customers, and employees, and that any improvements you make need to continue to satisfy their needs. Including them in your scope can help you work together to make even broader improvements than if you focus solely on what is under your control.

- It is important to plan for change. Make sure your continuous improvements provide flexibility for whatever the future may bring. New project types, new customers, new volumes, new products - these all need to be taken into account. If your improvements are focused on what you're doing today, such as putting a system in place to deal with a certain number of reviews per month, you may not be able to deal with what happens next month if the number of reviews significantly increases or decreases.

* There are different ways to start with continuous improvement. But the easiest one is "Start right now"

Understanding why you're implementing a continuous improvement strategy will help you avoid trying to force change where it isn't useful or necessary. Let a thorough analysis of your processes, products, and procedures dictate the changes you put in place.

Other Benefits of Continuous Improvement

The direct benefits of your continuous improvements are often easy to predict. You can calculate or estimate cost and time savings even before you implement the changes. There are other significant benefits, however, that you will not realize until your continuous improvement strategy is in place:

- Better Morale: Your collaborators and employees will benefit from the improvements and increased dynamism that continuous improvement provides. Continuous improvement projects are an opportunity for employees to step outside the box and have a meaningful and rewarding impact on their job.

- Better Acceptance of New Ideas: When your organization is used to accepting the status quo, new projects and opportunities can be seen in a negative light. With a continuous improvement strategy deployed, your teams will get used to and appreciate working with the notion that change is positive.

- Increased Motivation: When those you work with know they are empowered to observe, analyze and improve the way they work, they're more motivated than if they're expected to simply apply the same old methods and ways of working. They'll be more excited about their career future when they know they can have a positive impact on it.

We have all encountered resistance to change. It happens at all levels of an organization and needs to be managed. When you start communicating your continuous improvement strategy to your teams and employees, make sure you focus on the benefits. Some may assume it simply means more work.

They need to know that continuous improvement isn't in addition to what they're doing today but rather an integral part of it. It's a new way of looking at their old way of working. The goal of continuous improvement is to make every aspect of what they're doing better, easier, faster, cheaper, and more profitable to the business.

Involve Everyone

It's important to create a broad, encompassing continuous improvement strategy that can be shared and communicated across your entire unit, company or organization, depending on the scope of your role.

Treating continuous process improvement as a one-off project for a small group is a sure-fire way for it to be forgotten as soon as the first project is completed. Instead, make it clear that continuous improvement is a new way of doing business and that it should be applied by everyone and in all aspects of your business. Some great ways to make sure everyone is on board include:

- Communicate the strategy clearly and to everyone. Create a continuous improvement team and have them come up with a mission statement, guidelines, scope, and other details that can be shared for all to see. Let every employee know their ongoing contribution and dedication are vital.

- Have a kick-off event. Make it clear your new continuous improvement strategy is a big deal and that management is optimistic and 100% behind its successful implementation. Introduce the team and make it clear who is responsible for what and who the contact people are for different activities and sectors. Put in place a simple and inclusive way for employees to share ideas they have - like a suggestion box, internet forum, chat group, recurring ideas meeting, etc.

- Give concrete examples. "Continuous improvement" is a very broad term, and some people might not understand how it applies to their role, processes or products. Find some pertinent examples for your sector or industry. Show examples where your company has made improvements in the past, and explain how that can be a springboard for continued improvement.

- Highlight the benefits. You're not implementing continuous improvement for fun. The goal is to improve your business by removing waste, overlap, and redundancy and coming up with creative ways to streamline and improve the way you work. Let your employees know that continuous improvement can be applied to every single aspect of your business.

- Create several kick-off projects. While continuous improvement should become second nature in your workplace, in the beginning, you will need to babysit your strategy. A few high-profile projects can help to keep your continuous improvement strategy fresh in everyone's mind. Train and empower team leaders to closely follow the evolution of these projects, and solicit input from as many employees as possible.

If management isn't enthusiastic about continuous improvement in the workplace, no one will be. Find ways of bringing it up often, always highlighting the reason for it and potential improvements. Praise even the smallest improvements because employees might be hesitant at first to make suggestions.

Don't worry if the idea is slow to catch on. A continuous improvement strategy has no time limit, no endpoint, no expiration date. You're looking to change the mentality of a group of people who are more than likely comfortable and settled in how they do their jobs today. Remember that continuous process improvement isn't a new task added to your workload but that it permeates every single thing you do.

Start This Instant

Of all the workplace management decisions you can make, continuous improvement is the easiest to begin. Start right now. Consider what you have to do today and find a way to improve it. Then put in place a way to measure your improvement and check at regular intervals to see your progress.

* A convenient way to measure progress is by using some basic flow metrics used in Kanban

Remind yourself to think about "continuous improvement" every day until it becomes second nature. Pick three areas where you want to apply continuous improvement principles. To help you understand just how broad and all-encompassing a continuous improvement strategy is, look for the following examples within your organization:

- The Negative Case: Choose an aspect of your business that is clearly in need of improvement. Maybe you've been putting it off or minimizing the negative effect it has on your business. When it's obvious that something is not working the way it should, finding noticeable improvement is rewarding and encouraging. It will have a positive effect on your bottom line and bring attention to the usefulness of applying continuous process improvement.

- The Neutral Case: Choose a process, part or project that seems to be in cruise-control mode. These cases can be challenging, because while there may not be anything obviously wrong, you may struggle to pinpoint what can be done to make them better. You might also be tempted to leave well enough alone, so a neutral case will help reset your mindset and get you thinking about continuous improvement.

- The Positive Case: Look at your most successful business aspects and see what you can learn from them. Can you take best practices and transfer them to other areas or departments? Is it possible to make further changes that push these success stories to the next level? Are the people responsible for these positive results able to share their knowledge and skills to other people who will then become continuous improvement champions themselves?

The Right Instruments for the Job

One last tip for the successful creation, implementation and expansion of a workplace continuous improvement strategy is using the right instruments. Kanbanize by Businessmap is designed with the goal of continually improving how you run your business.

Having an accurate picture of the state of your stock, continuous improvement projects and key performance indicators at all times is key to assessing and planning your improvements.

If you don't measure and track your improvements, you'll never know what is working and what isn't. While some improvements can be done by intuition, you'll quickly find that after an initial improvement, you don't know where to go next.

With Kanbanize, you have powerful visual management tools designed with great flexibility. It doesn't matter what industry you're in, what type of business you run or what kind of services or products you provide.

Kanban can be applied to any type of organization, and you can pick and choose from the features and options that work for you. Don't try to shove a square peg in a round hole. Our software platform adapts to suit your needs today and also scales your business according to your future needs and growth. We apply Lean principles, which are a cornerstone of continuous improvement - one of the building blocks of Lean.

Experience the power of Kanban boards and build your continuous improvement strategy around an easy-to-use visual software. See how easy it is to collaborate with other members of your organization, whether they're in the same office or on the other side of the world.

Establish streamlined workflow, policy and tracking reports that get everyone on the same page and working to the common goal of constantly, confidently, and continuously improving.

Continuous improvement doesn't have to be complicated, but it does take some planning and dedication on behalf of management and leadership. Make the decision to turn your workplace into a continuous improvement success story and push your business to be more effective, more streamlined and ultimately, more profitable.

Establish short-term actions that will get you to your long-term goals. And remember, continuous improvement truly is continuous: Once you get started, a day won't go by when you're not finding new ways to improve your business!

Pavel Naydenov

Head of Marketing | Kanban | PPM Ops Certified

Pavel is a natural-born optimist with 10+ years of experience in the marketing field. By leveraging Kanban, Lean, and Agile practices for years, he drives brand growth and engagement through data-driven marketing strategies. He believes every message should express the fundamental values of a brand, and if delivered positively, it can change the course of its existence.