The culture of the company is the personality of your organization. It defines how people will interact and communicate with each other and how work will get done. That is why it can support the performance of the company, but it can also harm it.

Make no mistake, every organization develops a culture, regardless if that is a guided or an unplanned process.If you are on your journey to Lean operations, a necessary step is to integrate Lean values and models into your culture, as they will support your transformation.

When talking about a Lean culture, it is hard not to mention Toyota and its impressive results pioneering Poka Yoke, Gemba Walk, or Just-In-Time, to name a few. What we tend to leave out of the discussion though, is how Toyota got there. Did the tools come first?

"First we build people, then we build cars."

Fujio Cho

This famous quote from Fujio Cho, currently an honorary chairman of Toyota Motor Corporation, comes to underline the crucial role people play for the success of the company.

People, Culture and Lean

Company culture starts with the people. Many even describe it as made up of all of the life experiences each employee brings to the organization. While every team member has an impact on the culture, it is primarily influenced by the founder and the executives, due to their roles in decision making and strategic direction.

Next to (Lean) planning, (Lean) concepts, and (Lean) tools, Lean culture is one of the four components for successful Lean implementation. Often we see companies choose which one or two of the four they would like to implement. Primarily, this is because they do not understand that Lean is an overall system and represents a complete and comprehensive cultural change in their organization.

But What Is "Lean Culture"?

There are different definitions and concepts around what a Lean culture is. In some cases, the focus is primarily on improving processes. Others build upon that, including respect for people. However, the core always remains the same. In essence, a Lean culture is a learning culture driven by customer focus and oriented towards continuous improvement.

Generally, the following four distinctive dimensions describe the different pillars of Lean culture:

- Cultural Enablers - Lead with humility, respect every individual

- Continuous Improvement - Seek perfection, embrace scientific thinking, Flow and Pull value

- Enterprise Alignment - Think systemically, create constancy of purpose

- Results - Create value for the customer

Instead of going deeper into the theory and bore you, let me share with you a few examples from the Businessmap culture that explain the four dimensions a bit better:

Cultural Enablers

For starters, in Kabanize, we have a flat hierarchy and practice shared leadership. We believe no one has a monopoly on good ideas, and this is also manifested in our credo "We Are All Leaders." Respect for everyone is one of the company's core values, which also motivated our decision for multi-color branding, representing diversity and equality.

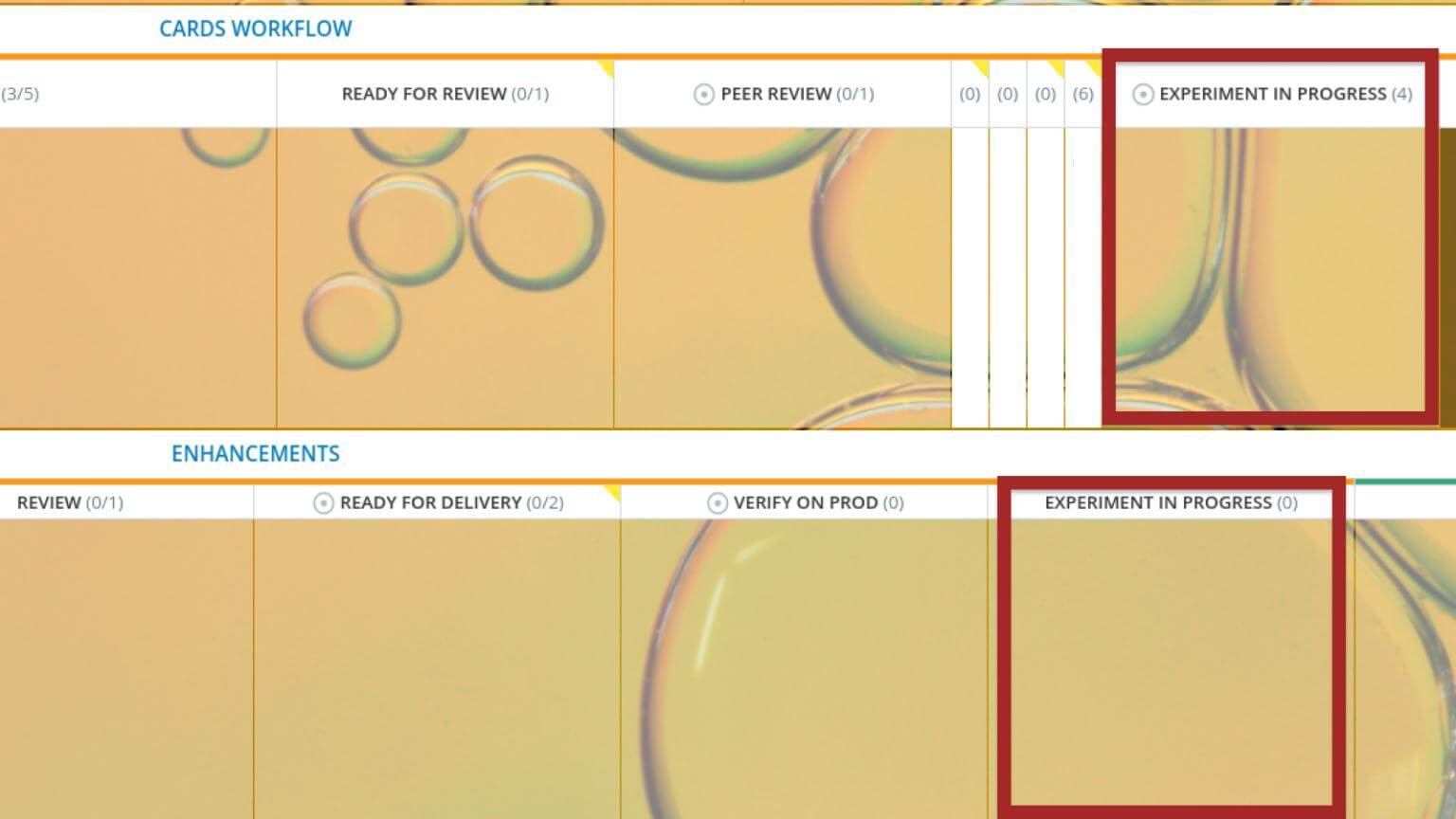

Continuous Improvement

Maybe "There is always a better way!" says it all, but continuous improvement is literally in our company's DNA. To be able to improve our organization's processes and product continuously, we have integrated experimentation and data-driven decision making as company standards. Experiments have even their dedicated place in our workflow.

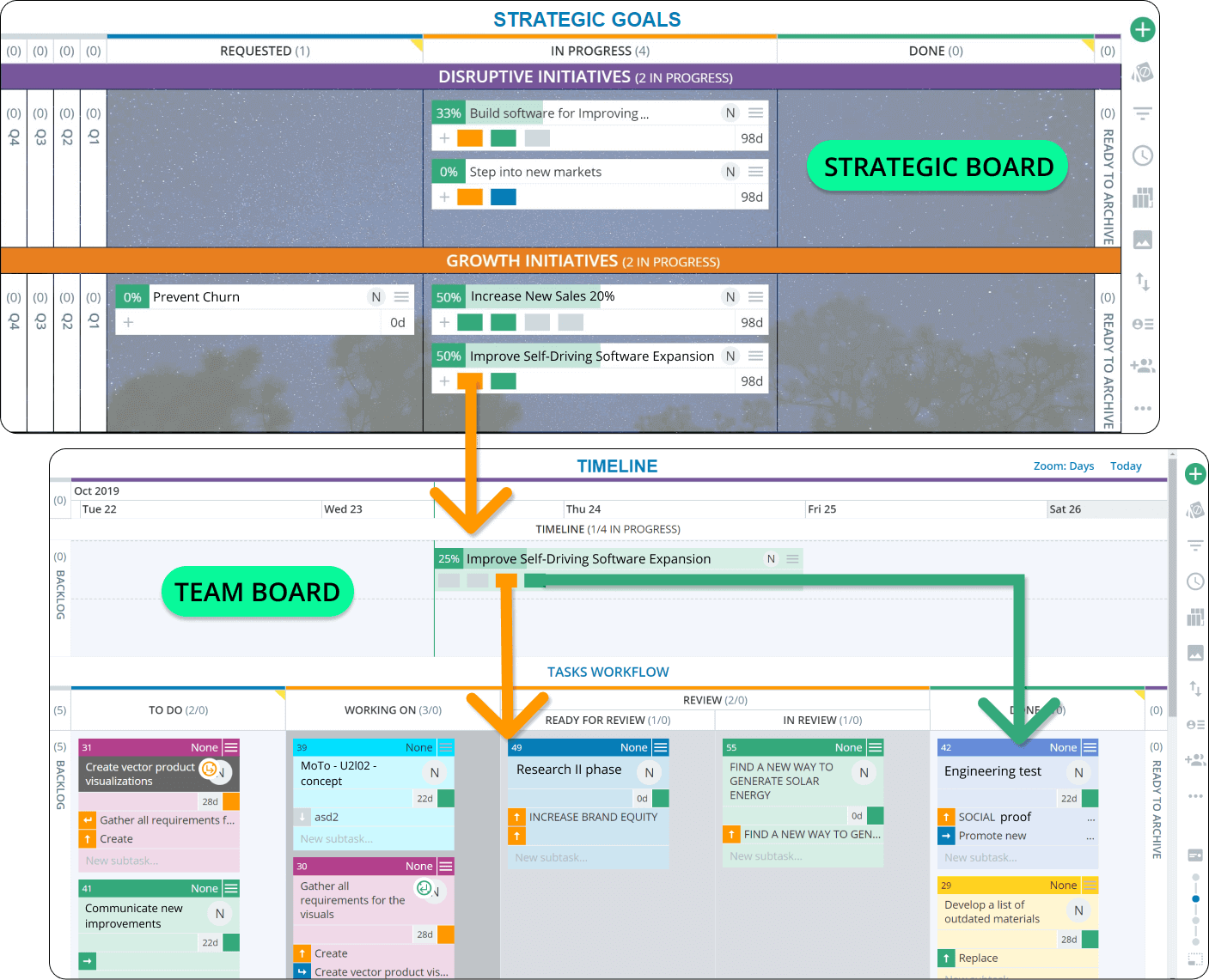

Enterprise Alignment

Enterprise Alignment can be a tough thing. Done correctly, though, it builds the bridge between the company mission and everyday operations. For us, the building blocks of this bridge are Hoshin planning and connecting strategic initiatives with projects and tasks on an operational level. This way, we create transparency in our operational activities and achieve alignment between stakeholders.

Results

One of our ways of delivering results and creating increasingly more value for our customers is through monthly product updates and constant product development. Each month we launch new features or introduce improvements to existing ones based on customer feedback.

How Do You Build a Lean Culture?

Creating a Lean culture is about getting everyone to see waste and remove it. It is about people questioning the things they do and acting on facts instead of opinions. Lean culture requires everyone to work together, not in silos. In some cases, it requires a mind shift. In other, it is more about agreeing on what we all collectively understand under waste or value.

Whatever the case, using tools can be very helpful, but they alone will not do the job. Here are two points to consider when trying to build a Lean culture:

Managers Must Lead the Way

As mentioned already, the leadership of the company has a significant influence on the company culture. For this reason, the managers must be the ones to lead the way, open the conversation, and make examples. An important point here is that managers in Lean manage the work, not the people. Focusing on workflow management will also create an environment of shared leadership, where everyone collectively contributes to the end result.

Develop a Culture Framework

A cultural framework plays the role of the company compass for new employees and also for people on the team who sometimes might wonder what the right thing to do is. It establishes guiding principles or behavioral expectations for the entire organization. By listing a set of standards and desired behaviors into a framework, you also create certainty, clarity, and alignment on how it is expected to do things in the company.

To make it a bit more clear, here are two examples of how behavioral expectations can sound:

- We expect punctuality and preparedness to support our team environment.

- We seek out root causes and make decisions based on valid data.

Behavior Challenges When Adopting a Lean Culture

Nothing harms your culture as much as systematic behavior, going against the values and standards you are trying to establish. For a Lean culture, the following three can be especially devastating:

Secretive About the Big Picture

It is common sense that you can not achieve enterprise alignment while you are secretive about the big picture. However, this is an often-seen combination, and it is not always even intended. Intransparency and lack of direct and timely communication between different departments can also be falsely interpreted as people being secretive.

To support a Lean culture in your organization, make sure important information is easily available to everyone. Also, minimize the amount of "surprise" moves and encourage regular exchange and discussions between the departments.

A healthy Lean culture needs a transparent work environment where the big picture is visible and clear to everyone.

Intolerance to Failure

Experiments will not always bring exceptional results. Not every new idea will be a winning move. For this reason, in a Lean culture, it is essential to show tolerance to failure. Otherwise, extreme criticism can create fear in your people and block experimentation.

A Lean culture is a learning culture, so it is of great importance to extract learnings from failures as much as from successes. Promote small-batch testing to minimize potentially harmful results from unsuccessful experiments. Also, as a company leader, make sure to speak openly about your failures and the learnings from them to make an example of how they should be analyzed and built on.

Importance to Output over Value

Lean is all about increasing customer value. This is why favoring output over value is just not compatible with a Lean culture and operations. Make sure producing and increasing customer value is accepted as the highest priority in your organization. Then evaluate your output based on this metric, rather than merely on quantity.

Last But Not Least

Your company culture is defining how people will get things done in your organization. To tap into the full potential of Lean tools and techniques, make sure Lean is also seen as a culture, not only as a methodology.

Pavel Naydenov

Head of Marketing | Kanban | PPM Ops Certified

Pavel is a natural-born optimist with 10+ years of experience in the marketing field. By leveraging Kanban, Lean, and Agile practices for years, he drives brand growth and engagement through data-driven marketing strategies. He believes every message should express the fundamental values of a brand, and if delivered positively, it can change the course of its existence.