Would you consider customer experience the most important indicator of strategic performance for your organization? More than 45% of organizations do. Indeed, a healthy relationship with your customers is among the critical traits of successful, growing, and sustainable businesses. Understanding, tracking, and improving your workflow efficiency is important to ensure your customers are satisfied with your service/product delivery.

But what is an efficient workflow? How do you track and measure process efficiency?

Let's discuss these topics and see what best practices organizations and teams from various industries employ to improve theirs.

First, What Is Workflow Efficiency?

Workflow efficiency shows you how much time you spend actively working on your process compared to how long it takes you to deliver work from start to end. The term stems from the Lean philosophy, which focuses on identifying and reducing waste on the path to greater flow efficiency.

Let's say your team members need 10 days for the preparation of a new policy, but they spend only 3 days actively working on the assignment. In that case, the workflow efficiency would be 30%.

But why do workflows become less efficient? Let's find out.

What Makes Your Workflow Inefficient?

Regardless of the industry, team size, or organizational level, waste is one of the most common challenges to process efficiency. According to the Lean philosophy, which describes 7 main wastes, all of its different forms are the main source of inefficient workflows. Let's take a look at some examples from our practice below:

- Non-value-adding activities. Aim at identifying value-adding and non-value-adding activities in your workflow to understand better where your bottlenecks lie and define proper optimization actions.

- Poor communication. You can prevent unnecessary delays and misunderstandings by centralized communication and knowledge-sharing across your organization.

- Context-switching and multitasking. Limiting the maximum amount of work in progress can bring the focus on the most pressing priorities. In the long run, avoiding multitasking can impact your delivery times and improve the efficiency of your workflow.

- Repetitive and manual activities. Allowing people to do meaningful work and reducing the risk of human-made errors is perfectly attainable through powerful automation and can significantly improve the flow of work.

- Not tracking workflow efficiency. While this is not a form of waste, it's an important point because it's related to continuous improvement. Understanding your work process, what causes delays, and where people get stuck should guide your improvement efforts. However, measuring the impact of these changes will help you unlock even more improvement insights.

Now, let's focus on some actionable steps toward optimizing your workflow efficiency.

4 Best Practices for Improving Workflow Efficiency

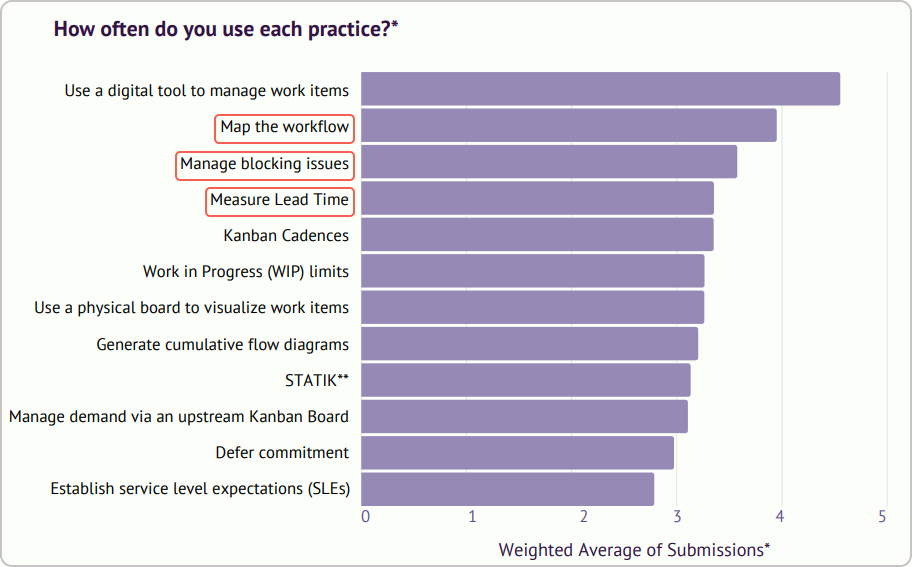

According to the latest research on Kanban, three of the most applied Kanban practices are visualizing the work process, managing blocking issues, and measuring lead time. Judging from our experience with Businessmap customers, we can't agree more!

Most used Kanban practices, Image credit: Kanban University

That's why we'll use hands-on workflow examples and how teams managed to improve their efficiency by applying the aforementioned Kanban practices.

1. Visualize the Entire Work Process to Address Ineffective Communication and Lack of Transparency.

The first practice to start with is visualization. Even though basic, it's a very powerful concept. Define each stage of your work process, what activities are completed at each step of the process, and ensure clarity and transparency.

Mapping the waiting (queuing) stages in your process can help you better understand how they impact your workflow efficiency, giving you clarity about both your value-added and non-value-added time. As a result, everyone can become fully aware of the way operations run, so communication can be naturally streamlined.

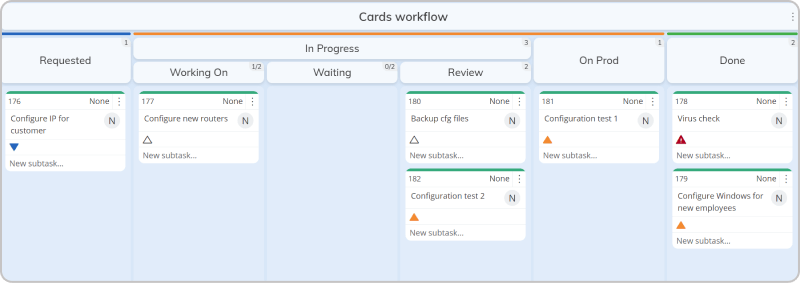

Mapping an end-to-end work process on Kanban boards

For example, mapping the whole operational process as accurately as possible has allowed the American construction company BMWC to establish a clear work breakdown structure, better communication, and reliable metrics to analyze its workflow efficiency.

To achieve this, Kanban boards have been successfully implemented to visualize the flow of design, construction, BIM/CADD, fabrication, installation, and quality control projects. This allowed, for instance, to track in real-time the processing of a request from its initiation to delivery. (BMWC Case Study)

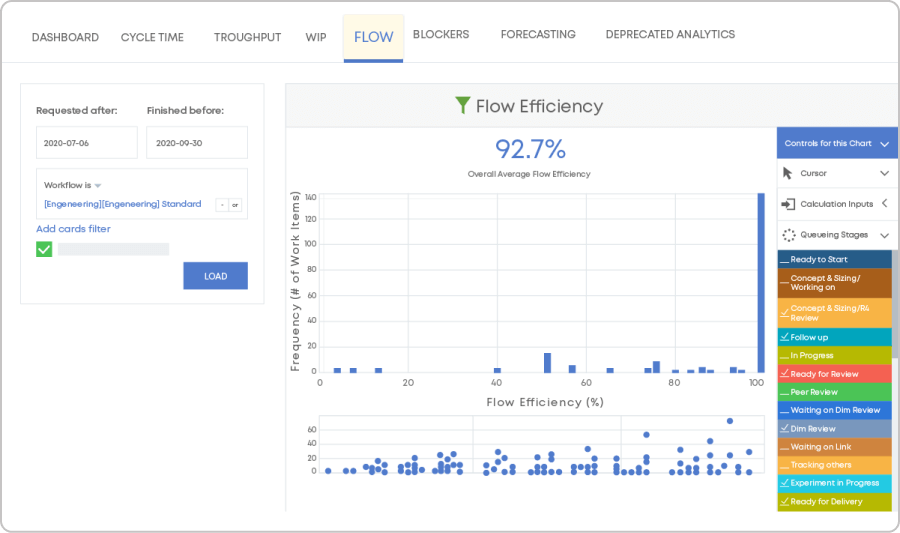

One of the great benefits of using a digital Kanban board is that it allows the accumulation of data you can learn from. Combining a Kanban board with a flow efficiency chart can help you gather data about the work items that have passed through the process for a given period of time and show you how efficiently you delivered them. You can use that information to identify redundant steps in your process, bottlenecks, and dig deeper into optimizing your service delivery.

Measuring workflow efficiency using a Flow Efficiency chart

2. Manage Blocking Issues to Reduce Waste and Improve Delivery Times.

"All we are doing is looking at the timeline from the moment the customer gives us an order to the point when we collect the cash. And we are reducing that time line by removing the nonvalue-added wastes."

Taiichi Ohno, creator of Just-In-Time production system

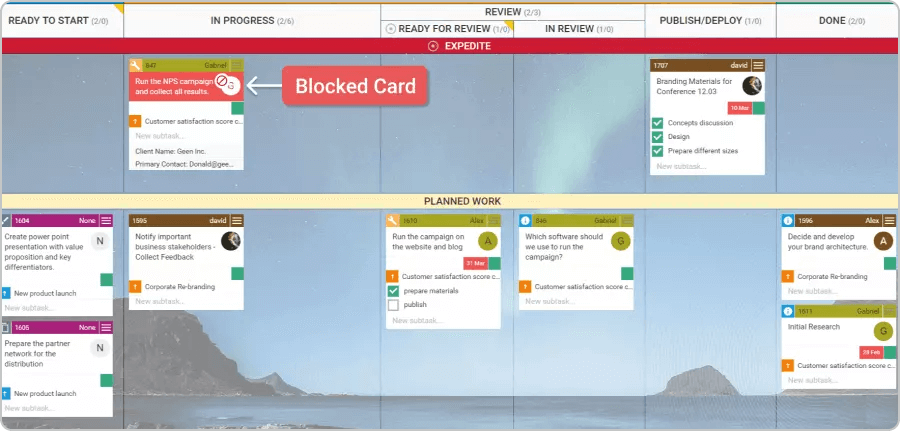

The efficiency of your workflow depends heavily on eliminating impediments. In addition to non-value-adding steps in your process (such as queue and waiting stages), unforeseeable events can impede your workflow, too. In Lean philosophy, we strive to reduce such events as much as possible. But how do you notice what's blocking your process?

To manage their innovation projects/initiatives, global chemical player Schlenk's R&D division introduced the use of Kanban boards. By visualizing all items passing through the board, the team exposed all the issues and dependencies causing delays. Elevating the process blockers using visual signals showed them exactly where they needed to improve. As a side effect, they gained a better understanding of the relevance of different work activities. (Schlenk Case Study)

Visualizing work process blockers with visual signals on a Kanban board

3. Reduce Context-switching and Multitasking by Limiting the Work in Progress.

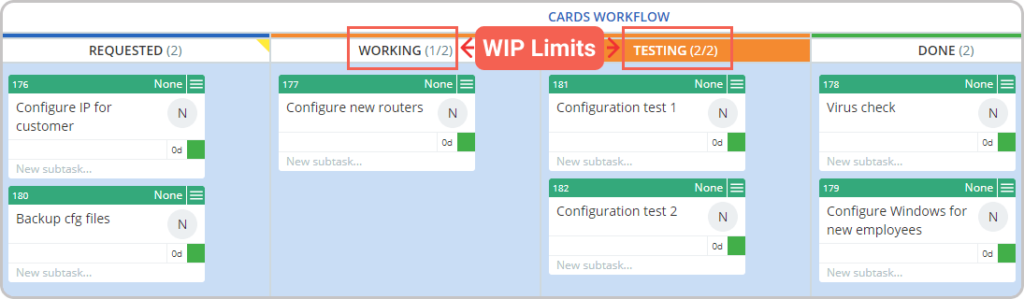

Overloading capacity levels and multitasking is oftentimes the leading cause of workflow inefficiencies such as long delivery times. A detailed visualization of your workflow will help you properly align people to the exact operational steps and eliminate the need for status updates.

Besides establishing clarity about the flow of activities, restraining the work in progress within your process can significantly impact context-switching and reduce the stress levels on your team members.

A demonstration of the power of visualization and limiting work in progress comes from the aeronautical engineering company Aerosud. Within just 3 days of applying both practices alone, their IT group was able to double the team's throughput. Stunning results! (Aerosud Case Study)

Visualizing WIP limits of a work process on a Kanban board

4. Eliminate Mundane Work and Rigid Processes through Work Automation.

Increasingly, automation affects both individual and team efficiency. As the demand for modern workflow automation systems grows, that market alone is expected to reach more than $26 billion by 2025, up from $4.8 billion in 2018. That tells you how beneficial automation can be for your business.

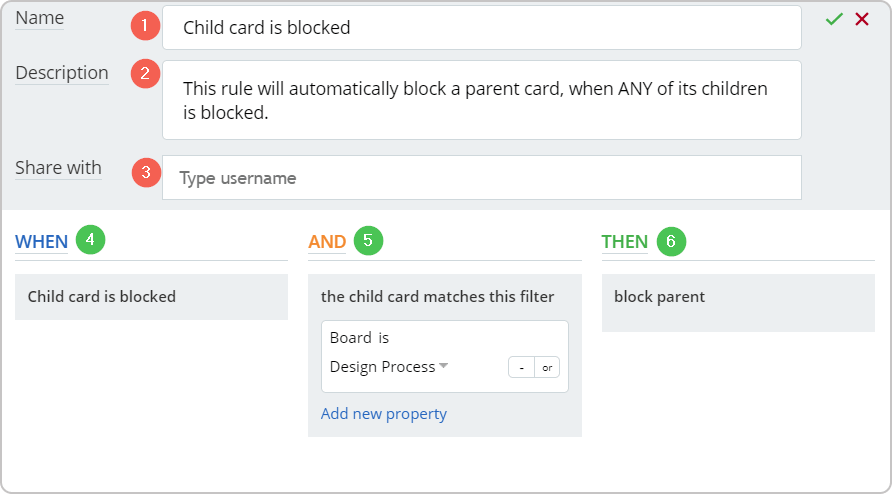

Indeed, automation was the key to smoothing the workflow on the BMWC's fabrication floor. With visual signaling and automation rules, anything that interferes with the process flow gets noticed. In their scenario, the company used automation rules to alert the team about issues.

For example, whenever a work item was blocked and that was part of an initiative, one of the BMWC's teams used automation to automatically block the whole initiative. This contributed to the faster resolution of issues by promptly drawing the attention of various stakeholders.

Activating a "Child card is blocked" automation rule

Tare manyad of possibilities with automation alone, but we value your time, and we'll leave you with this. For now!

Back to You!

I hope now that you are eager to try out the Kanban practices in your workplace and observe their impact on your workflow efficiency. Agile methodologies can certainly help you streamline your work processes. But what matters is to get started!

Iva Krasteva

SEO & Content Creator Expert

Analytical. Driven by constant learning and knowledge. Fascinated by people's creativity. Admiration for intellectual property, copywriter and SEO. Passion for nature's beauty, comic books, pop art and cinema.