"Respect for people" is one of the two pillars of Toyota's corporate culture and the Lean management philosophy. Yet, people think it's just about being polite.

If you ask 100 top-level managers, "Do you respect your employees?" you will probably receive a hundred answers, "Of course, I treat employees with respect and dignity." If your answer is similar, then you are in trouble.

Being polite to co-workers and maintaining good relationships should happen by default. Toyota's "Respect for people" is a much wider concept that should affect the way you see and maintain processes for the sake of your company's future success.

What Is Respect for People in Lean?

Respect for People is a foundational pillar in Lean philosophy, integral to fostering a collaborative and efficient workplace where continuous improvement thrives. This principle underscores the importance of valuing every team member, acknowledging their contributions, and empowering them to share insights and ideas.

Why Is Respect for People Important?

By embracing the concept of Respect for People, organizations create a culture where trust and mutual respect drive innovation, leading to enhanced productivity and a more engaged workforce. Respect for People has the power to transform the traditional top-down management approach into a dialogue where every voice matters. Respect is strategic, as it taps into the collective intelligence of the team or organization to solve problems and improve.

Five Ways to Embed Respect for People in the Workplace

Here are five ways to harness the power of the Lean idea in your environment.

1. Respect for People's Opinions: Create Opportunities for Feedback Exchange

Listening to opinions is easy, but not enough. You need to look after them and create a sharing culture among all hierarchy levels. Workers who are on the field probably have the best understanding of how processes actually happen. This makes them a gold mine for generating new ideas and achieving continuous improvement.

For instance, ask your team if there is a problem or if something can be done better. Then, discuss what may have caused the problem. Establish dedicated meetings for the same purpose and do this on a regular basis. You will be surprised by the amount of information you will receive and its practical application. After all, the people who do the job can provide you with top-quality feedback.

Having different points of view is priceless. But this is just the beginning of the journey.

2. Respect for People's Ideas: Demonstrate Shared Leadership

After collecting a large number of opinions, you have to proceed with finding a solution. Many high-level managers are tempted to gather all the valuable information and then try to develop and propose a solution on their own. Why? To steal the spotlight and take all the credit? Don't do this.

First, there is a much higher chance that the front-line team members will provide highly efficient suggestions for improvement. Your team is familiar with the daily work in detail, and every member can give a proper suggestion because they know what exactly may cause a problem. They see it every day.

Second, if you try to take all the credit, you will close the doors for future improvements. Imagine, if you do this, the next time you go and ask your team for good ideas, you will only receive silence. No one will trust you. In other words, your team will keep their ideas, and probably they won't even care about the company's chosen path or strategic goals.

If you really want to apply Lean management principles and make them work for you, remember that Lean encourages split responsibility and shared leadership.

3. Respect for People's Ability to Challenge and Think Aloud

First, you tried to collect some opinions. Then, you discussed ideas. So far, so good. However, you need to create an atmosphere where people not only share their points of view when being asked but they raise questions and challenge the process without being asked.

As outlined in Toyota's Way internal documentation, "We accept responsibility for our conduct and for maintaining and improving the skills that enable us to produce added value." Challenge is of great significance in the "Respect for People" notion.

Blindly following rules and orders is much easier for workers but devastating for your company's future. If you want to be a lean leader, let your team challenge the way they work. They may find a much better way to do their job and to be more efficient and productive.

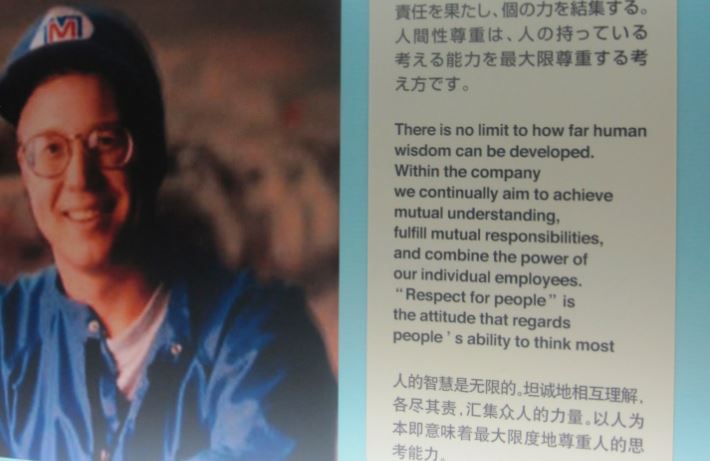

Photo by: Mark Graban

Photo by: Mark Graban

Lean organizations, such as Toyota, try to keep their employees highly motivated by allowing them to be challenged. In one of Toyota's factories, there is a poster saying, "Respect for people is the attitude that regards people's ability to think most". I guess it makes you understand that people's ability to think most and challenge will make your team or company a continuously improving unit.

4. Respect for People No Matter Their Area of Expertise

Sometimes we are trapped in commonly accepted norms. This is how you may reject valuable suggestions coming from John, the developer, to improve some processes in your marketing team. Why? Because John is not a marketing guy. However, sometimes colleagues from other departments may suggest a much better solution for your problem because they are not stuck in your daily routine and they don't have the same boundaries that you have. That's also the premise of cross-functional teams' success.

As human beings, we like to put labels, and we miss many opportunities by doing so. Toyota's "Respect for people" culture teaches us the exact opposite. To evolve continuously, we need to challenge ourselves constantly, listen, learn, and not underestimate others.

A real-life example from Cassandra Lin comes to notice that you should be open to new ideas. No matter where they come from. The 13-year-old created a recycling program that uses food grease from local restaurants to heat the homes of underprivileged community members.

If a 13-year-old girl can give such an idea, imagine what your colleagues' potential is and what you can miss by ignoring them.

5. Respect for People's Limits: Encourage Focus

Even the most efficient modern machinery has limits. Then what about us people? We all have our physical, mental, and emotional limits, and if we cross them, we eventually turn into a burden not only to ourselves but also to the company we work for. Keep this in mind every time you give your employees extra work.

If you overload your team, sooner or later, occupational burnout will appear. Consequently, productivity levels will decrease dramatically before you even realize it.

You have probably heard about kanban, a Lean-based method famous for its positive impact on productivity and efficiency. It is not accidental that one of the major kanban practices is focused on limiting work in progress.

The practice of limiting the work in progress (WIP) prevents the whole workflow from overloading, and it focuses on a single task at a time. Over the years, it has proven to be much more efficient than multitasking. And it is not just a statement - it's a scientific fact. Executing more than one task splits the brain, and errors multiply.

As a manager, you will probably want everything to happen as fast as possible. But be careful because, in the end, you may receive badly executed work, internal conflicts, and loss of valuable employees.

A Two-Way Street

We’d like to leave you with a quote by the Lean proponent, keynote speaker, researcher, and entrepreneur Nigel Thurlow reflecting on respect for people: "This is not a one-way street!". In Lean culture, everyone is part of a bigger collective where participation, support, challenging, and accepting challenges are all done in the name of creating value.

Respecting people enables teams and managers to learn and improve on a regular basis. In other words, it is a mandatory prerequisite for achieving continuous improvement across the hierarchy.

Actually, the two major Lean pillars of the Toyota way are interrelated in a very interesting way. As Mark Graban from leanblog.org describes it: "We practice continuous improvement because we have respect for people...we practice respect for people by engaging people in continuous improvement and challenging them to perform better...for the sake of our customers."

Pavel Naydenov

Head of Marketing | Kanban | PPM Ops Certified

Pavel is a natural-born optimist with 10+ years of experience in the marketing field. By leveraging Kanban, Lean, and Agile practices for years, he drives brand growth and engagement through data-driven marketing strategies. He believes every message should express the fundamental values of a brand, and if delivered positively, it can change the course of its existence.