Introduction

GE Aviation Czech (GEAC) is the Turboprop division of GE Aviation, a world-leading provider of aircraft engines and related components and systems. The company recently embarked on the development of Catalyst™, the first clean sheet engine in more than 30 years for the turboprop segment.

The end goal of the development program is to certify the new engine for commercial flights - a process that involves hundreds of engineers over several years. They work closely together to manufacture, instrument, and assemble the very first engines before they go through draconian testing in specialized test centers.

Initial Challenges in the Program

When they started the program, there was no tool in place to manage the workload, and it wasn't very easy to understand what the team needs to prioritize today and deliver over the following weeks.

At first, the team kept the work going with lengthy Excel trackers and PowerPoint presentations for management communication. Their effort to take control started with Trello, and its simple interface worked great as long as they had only one engine to deliver. Without the automation and card links options, with time became increasingly overwhelming to keep the Trello boards up to date. As the program ramped up, the team needed a more powerful tool to deliver several engines in parallel, which allows to cram many data onto one board and easily slice them to see the tree from the forest.

Key Results

Implementing Businessmap (formerly Kanbanize) and focusing on value delivery brought several key results for the GE Aviation team, working on the project.

Developed a work breakdown structure and strictly mapped the process to define better their value streams

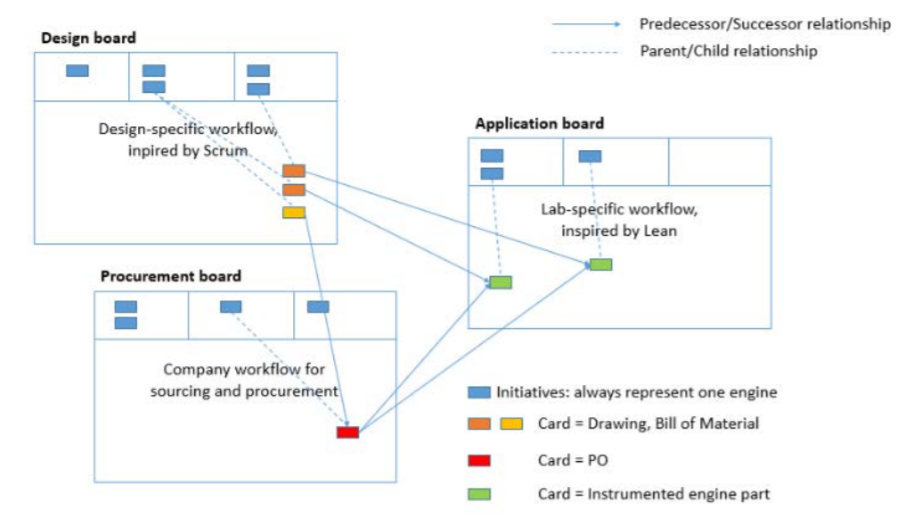

The Businessmap Software Platform allowed the team to go from visualizing everything on one board, to building a network of boards, enabling them to tailor individual workflows that suit their preferences. Thanks to the fully customizable Kanban boards, the team members were able to recreate the uniqueness of their workflow in the software. They managed to visualize the entire value stream of the program connecting several Kanban boards.

Built a common understanding of when work is done

The work management software allows teams to visualize explicit work rules directly on the board (not in a 200-page company process book) to build a common culture when the team members come from different backgrounds. Maturing in their use of the software and refining their workflows, over time, the team included simple "Definition of Ready" and "Definition of Done" checklists on the boards.

"Initially, I just want to track my deliverables, but mapping the workflow had a completely unintended, yet amazing effect: the team built a common understanding of how work gets done."

Gained real-time visibility of all active projects and dependencies

For the project manager, it's extremely valuable that the Businessmap Software Platform "bridges the gap between the abstract project plan and the day-to-day work". Being able to visualize the process from beginning to end on related Kanban boards, and also to use visual signals to highlight relations between tasks, dependencies, and blockages allowed the team to have an up-to-date overview of all project elements at a glance.

As a result, Benoît Guillaud, Project Leader of the program, stated that one person now does the work of 3 people compared with the days before the tool's implementation!

Download Full Case Study as PDF