In traditional project management, the Gantt chart is one of the most widespread tools for planning work, assigning starts and end dates to tasks, and controlling project activities against the initial plan. We will not argue if this is wrong or right. But let’s clarify that building a Gantt chart is acceptable in contexts with low variability. However, in the dynamic and flexible work environment of knowledge work, they can be a real nightmare.

Here, contrary to focusing on exact dates, Kanban planning offers an alternative based on your workflow historical data rather than on your gut feelings. In other words, planning with Kanban shifts the mindset from working with strict deadlines to relying on data-based probabilities.

Table of Contents

Why Kill the Gantt Chart?

The Gantt Chart is a useful tool if you want to visualize dependencies or sequencing. However, when you attach start and end dates to the individual work items, you become the root of all evil. Why is that? Because:

- We have the means to twist hands, a.k.a “Project X is late, you will work on the weekend”.

- We have the means to justify bad decisions, a.k.a. “They want us to do it by Friday. Let’s not do what we have to, but what we can”.

- We know when we are on time, a.k.a. “The charts are green, but no one knows what the heck is going on around here”.

- We have some more time, no rush, a.k.a. “The task is planned for 3 days. Let’s make sure it takes at least that long”.

As it is clear, the Gantt chart is heavily focused on scheduling - assigning fixed start and end dates for individual tasks. Now imagine scheduling all tasks in a website development project. It is not only unrealistic to approach knowledge work projects in this way. It also creates a lot of waste.

For this reason, Kanban planning is what we recommend for knowledge work projects. Focused on outcomes, delivery dates, and cycle time analysis, this approach allows more flexibility. Planning the Kanban way acknowledges that we do not have control over the future and refuse to go into unnecessary details. It represents moving from a deterministic to a probabilistic approach and working with ranges and probabilities instead of fixed deadlines.

Planning on a Kanban Board

At Businessmap, we call the Kanban board “The new Gantt Chart”. Of course, you cannot translate one into the other without losing some of the characteristics, but there’s a pretty good correlation, making Kanban Planning possible. Whether you want to plan your projects weekly, monthly, quarterly, etc., the Kanban board allows you to do that.

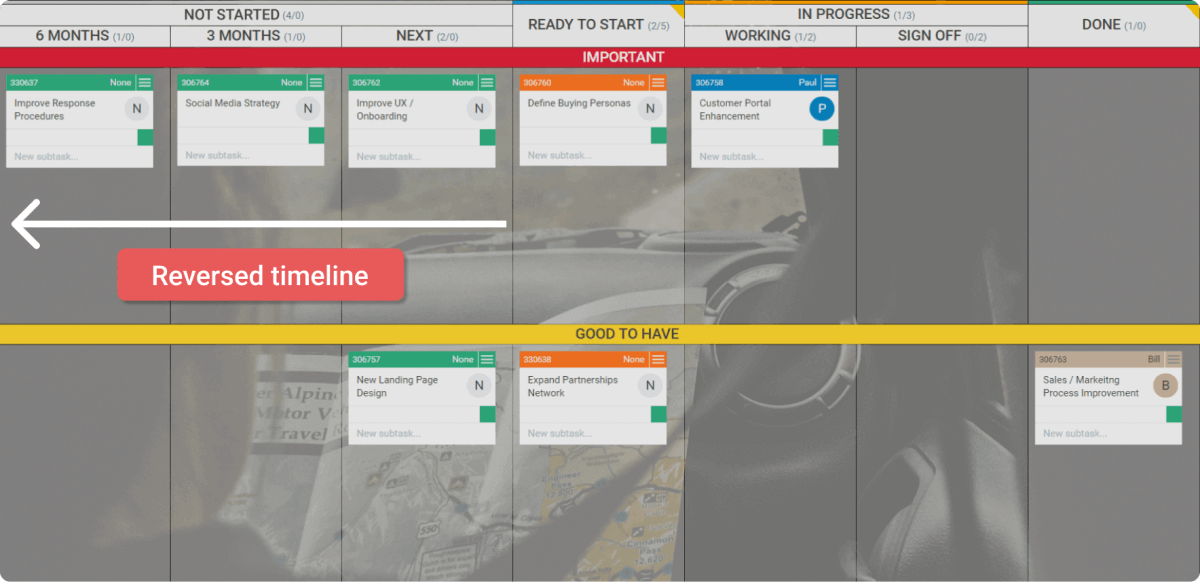

Imagine that the “Not Started” area of your Kanban board is a reversed timeline – the rightmost column is “now” and the leftmost, sometime in the future:

With this basic timeline in place, we can easily use stickies to plan when some items are most likely to be delivered. For example, suppose one item has to be expedited or postponed. In that case, we take the Kanban card and move it to another column of the Kanban board, changing the card's priority.

That's pretty much the Kanban Planning approach – reorder the stickies to be in the right column. Of course, we should use Kanban cards if we are using Kanban software for this purpose.

The Kanban board also helps your teams plan their daily and weekly activities. It gives a constant up-to-date overview of all work items' status in the pipeline and the different tasks' priority. This way, when capacity frees up, people have all the needed information to proceed with the most important task in the queue.

Depending on how you prefer to plan your strategic goals, you can also create dedicated columns on your board representing your different planning horizons.

This way, planning on a Kanban board will help you keep your upcoming projects and future goals in front of your eyes.

This way, planning on a Kanban board will help you keep your upcoming projects and future goals in front of your eyes.

10 Years Kanban Experience In 1 Free Book.

Project Manager's Guide to Kanban

How Do We Know if Kanban Planning Is Accurate?

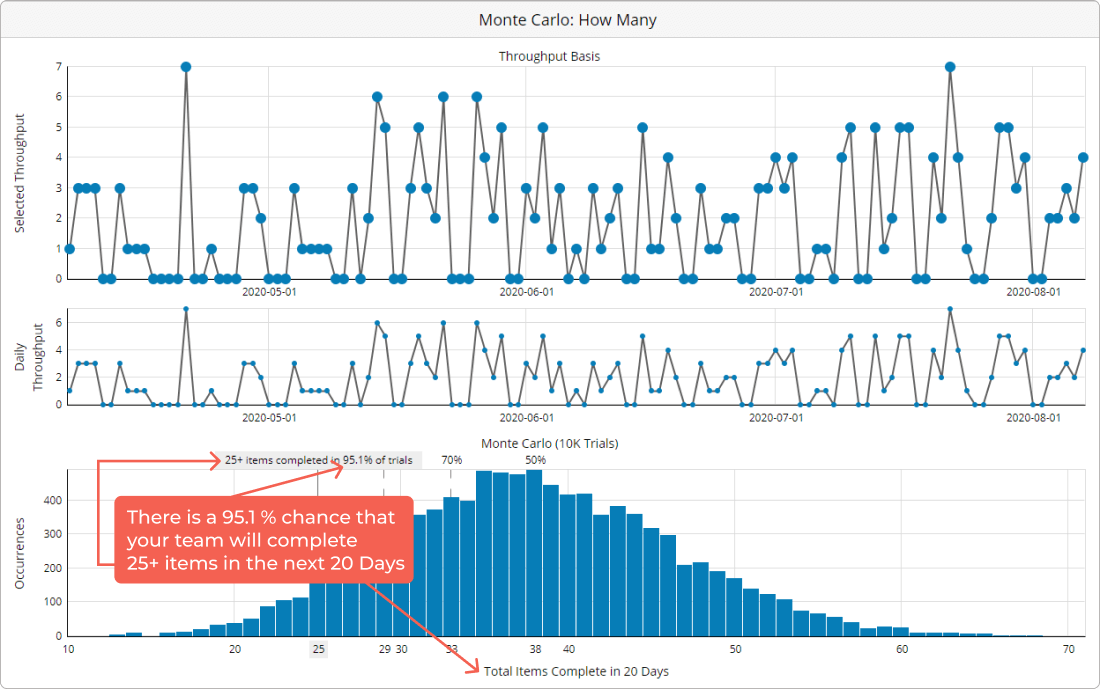

In Kanban, metrics play a central role, and the method's planning and estimation aspects make no exception. Focused on flow stability, measuring cycle-time, and throughput, Kanban helps you collect data on your teams and company's performance. For example, when you have a stable workflow, you could expect similar work items to have a similar cycle-time. Then you could also use average cycle-time and throughput numbers to calculate and predict with high probability when upcoming projects are expected to be finished.

Although that might sound like a simple calculation, it could cost a lot of time to go over different numbers and scenarios when managing multiple projects. To make this easier, the Analytics module in Businessmap offers Monte Carlo simulations. This powerful analytics tool does the calculations and predictions for you to give a precise estimation by just taking a look at its diagram.

Not only that you do this in a fraction of the time, you’d need a detailed plan, but estimations are based on historical performance data rather than your gut feelings.

Not only that you do this in a fraction of the time, you’d need a detailed plan, but estimations are based on historical performance data rather than your gut feelings.

Next Generation Project Forecasting

The Businessmap software platform allows you to create projects on a Timeline or Initiative workflow and break them down into smaller chunks, as you can see in the image below.  But, here comes the good part.

But, here comes the good part.

You can forecast every project you create in the system.

Thanks to our forecasting feature, you can get different scenarios for the completion of a given project. The forecasts range from optimistic to very pessimistic. You have to be aware that the forecasting feature will be as good as your historical data is. If you have a stable, predictable process, your forecasts will be very accurate.

You have to be aware that the forecasting feature will be as good as your historical data is. If you have a stable, predictable process, your forecasts will be very accurate.

Find more information on the project forecasting topic.

We offer the most flexible software platform

for outcome-driven enterprise agility.

In Summary

Managing projects, the last thing we should be doing is trying to schedule or estimate our work with no real data behind the plan. Instead, we should concentrate on advancing our progress with planning based on actual historical data and adjusting at each stage. Here Kanban planning offers a solution:

- With Kanban planning, you break down projects into tasks and estimate how long your team will need to complete all tasks.

- It is not focused on giving an exact end date but on providing a range of days (for example, between 25-30) your team will need to finish the project.

- With Monte Carlo simulations, the Kanban estimations are based on historical performance data, representing an accurate prediction of the project's overall cycle-time.

- Planning on a Kanban board allows you to transform your board into a reversed timeline and visualize your upcoming projects and future goals next to your current work.

This way, planning on a Kanban board will help you keep your upcoming projects and future goals in front of your eyes.

This way, planning on a Kanban board will help you keep your upcoming projects and future goals in front of your eyes.

Not only that you do this in a fraction of the time, you’d need a detailed plan, but estimations are based on historical performance data rather than your gut feelings.

Not only that you do this in a fraction of the time, you’d need a detailed plan, but estimations are based on historical performance data rather than your gut feelings. But, here comes the good part.

But, here comes the good part.  You have to be aware that the forecasting feature will be as good as your historical data is. If you have a stable, predictable process, your forecasts will be very accurate.

You have to be aware that the forecasting feature will be as good as your historical data is. If you have a stable, predictable process, your forecasts will be very accurate.